ERGONOMICS

"Gausscope is an ergonomic probe, easy to handle in any working situation. Its natural grip makes it precise and agile."

On a production line, just using a multimeter combined with visual, thermal and vibratory analysis does not make it possible to see what pieces of equipment are generating disturbances of the current.

Gausscope makes it affordable and practicable to analyse a current to identify signs of fatigue, faults or electrical failure in industrial equipment to avoid and reduce production downtime

Gausscope is a portable probe supplemented with visualisation software that facilitates the interpretation of the anomaly and provides a level of information that is not possible with a current clamp or oscilloscope.

“Now you can perform faster corrective maintenance diagnostics and adopt a predictive maintenance approach for drives, motors, power supplies and industrial electrical equipment with a safe and portable tool.

Customer references and operational use.

A SNCF maintenance workshop uses it for breakdowns.

At Veolia, it is used to ensure continuity of service in an incineration centre. It is already being used by some twenty manufacturers to understand complex faults more quickly.”

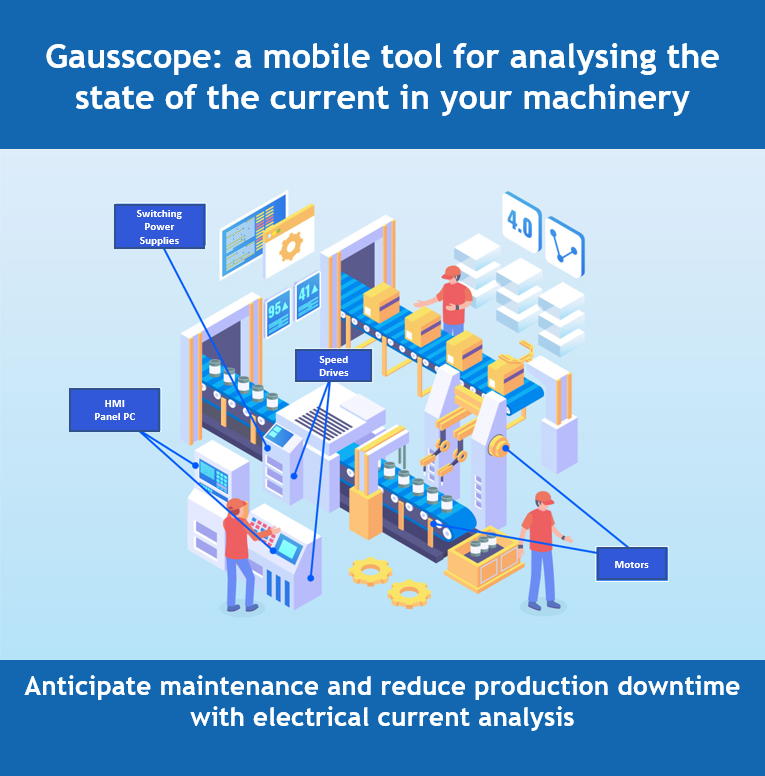

Gausscope: a mobile tool for analysing the state of the current in your machinery.

Current analysis facilitates maintenance to anticipate and reduce production downtime.

ERGONOMICS

"Gausscope is an ergonomic probe, easy to handle in any working situation. Its natural grip makes it precise and agile."

MOBILITY

"Gausscope is combined with a proprietary visualisation and interpretation program embedded on a tablet or laptop which makes it usable in mobile mode by everyone."

SAFETY

"No need to dismantle and/or clamp electronic components, wires or cables; diagnostics are quickly performed with minimal electrical risk."

SAVING & ENERGY

"Gausscope combines economic and environmental benefits by extending the life of equipment."

SMART

"With Gausscope, there is no need to dismantle equipment or change parts to find out if they are faulty."

ADDITIONAL SERVICES

"Gausscope confers access to additional services offered by e-nergie: advanced training in the interpretation of electrical signals, remote or face-to-face diagnostic assistance, signal inventory recording for predictive maintenance and equipment repair."